A process that was perfected 3.5 billion years ago, to remove carbon dioxide and give the earth its life-enabling oxygen atmosphere, is being used by Tattva, a spinout from UCL, to create superlight, biomaterial for building components.

Co-founder Prantar Tamuli has developed a unique process that forms a carbon-sequestering 3D material in just days, while offering a rare combination of properties: high strength, excellent thermal and sound insulation, fire resistance, and translucency.

Sustainable alternatives for the construction industry

Biomaterials offer an alternative to the cement and plastics widely used in the construction sector – which accounts for 37% of global carbon dioxide emissions. But the challenge for innovators is how to offer higher perceived value as the industry is cost-sensitive, conservative, and highly regulated.

Steven Roberts, co-founder and director of Tattva, a spinout from the UCL Bio-Integrated Design Programme, explains that an increase in the cost of carbon would help tip the balance in favour of biomaterials and accelerate their development.

“The Tattva production process locks up one tonne of carbon dioxide for every 4m3 of material created, but this alone is not sufficient for market penetration. New materials need to look similar to existing products for market adoption, but also to offer additional properties in order to justify the price premium.”

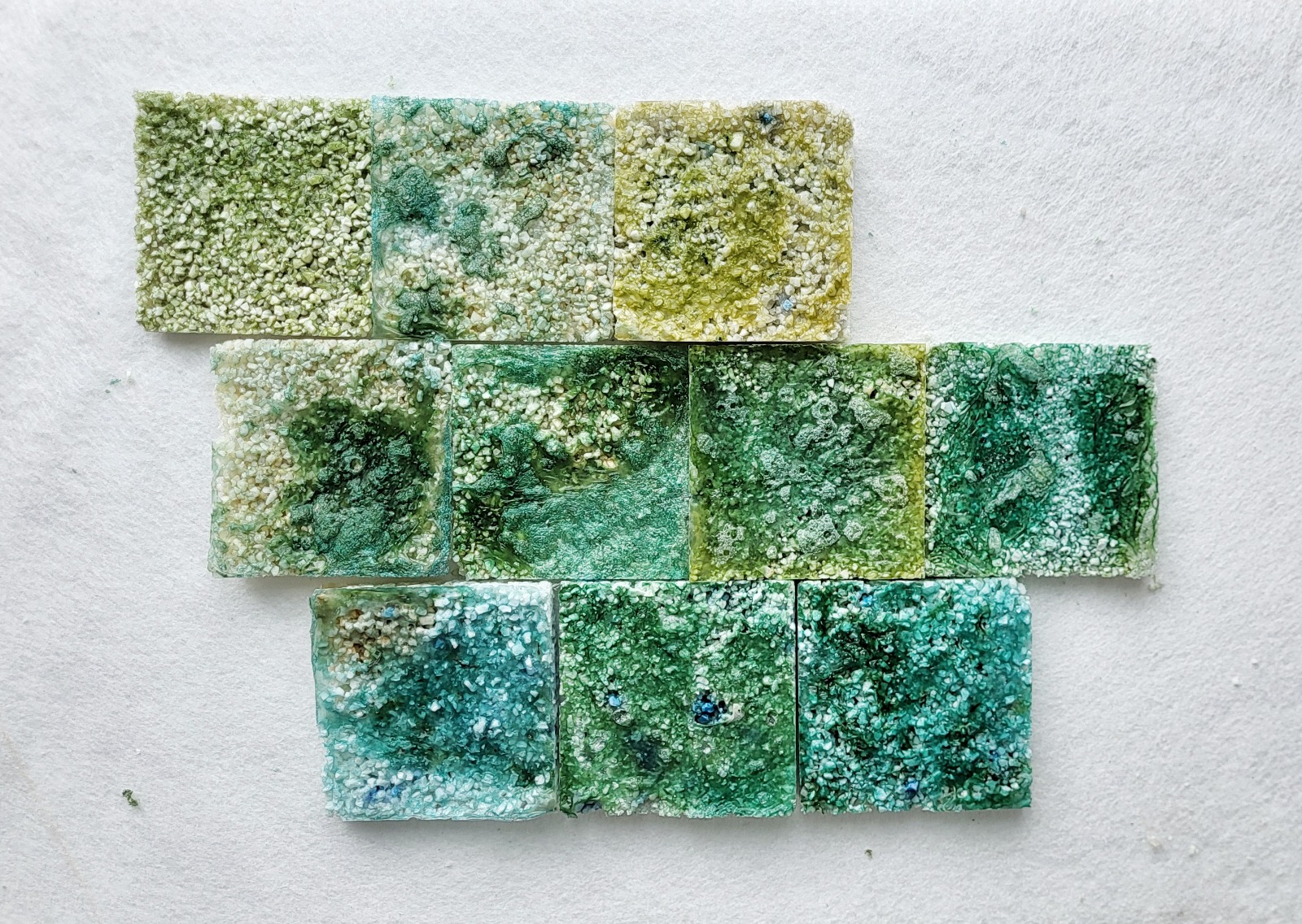

It was the combination of novel properties offered by Tattva’s first product Stromate, that was of interest to Catnic, part of the multinational Tata Steel Group. Tattva and Catnic have just completed an innovation sprint to explore the potential for using Stromate as an alternative to conventional materials.

Unique biomaterial locks up carbon through photosynthesis

It was during lockdown that co-founder, Prantar Tamuli (UCL Biochemical Engineering) became inspired by a photosynthetic cyanobacteria, Kamptonema animale. In nature it grows in long strands, creating sticky biofilms that trap, bind and cement grains of sand and calcium.

This solidifies into a fossilised rocky structure, called stromatolites, capturing the carbon as calcium carbonate, and releasing oxygen into the air. Significant amounts of carbon dioxide are removed during the initial bio-mineralisation process but, as the stromatolite remains a living structure, this process continues for eternity at a low level. Prantar saw its potential as a novel biomaterial.

Naturally bio-mineralisation takes thousands of years, but Tattva has developed a new process to culture the cyanobacteria using a similar technology to that used in vertical farming.

Prantar explains: “The biggest challenge of biomaterials is scaling them to meet the size and demand of the building industry, and we are at the forefront of resolving that challenge.

“We can grow Stromate at metre scale in 10 days or less. This has being made possible by developing a rapid-growing cyanobacterial ecology of more than 25 species, integrating insights from fields like artificial tissue engineering, and designing the most advanced solid-state photobioreactors to date.”

The goal is a completely automated facility growing strong, lightweight modular components for use in construction, landscaping, or civil engineering. The organic process would also enable the components to be moulded into complex shapes.

Novel combination of properties

Stromate offers a rare combination of high value properties. It can be used to create translucent panels that are as strong a brick (3MPa) but five times lighter, while offering A1 fire resistance and significant sound and heat insulation (0.03 W/mK).

Tattva has found a method of controlling the growth the bacteria to create variations of these properties to meet a particular specification. Potential applications include acoustic sound insulation for open plan offices; decorative bricks for letting in light while maintaining privacy and temperature; a fire-resistant alternative to polystyrene foams.

Carbon sequestering alternative that offers strength, fire resistance and thermal insulation

One company that is interested in investigating greener construction materials is Catnic, a leading manufacturer in steel lintels and roofing materials. The company was looking for innovation to support its net zero journey, many of the products used for construction are derived from fossil fuels.

Catnic quickly saw that Stromate offered a more environmentally attractive alternative material that offered many novel properties, Tattva’s proposal was accepted and the companies have collaborated on an innovation sprint to provide a proof of concept.

Need for change

“The construction industry must evolve toward lower-carbon solutions and Tattva’s pioneering bioengineered materials offer a truly disruptive approach,” says Richard Price of Catnic. “Stromate’s ability to sequester CO₂ while delivering strength, fire resistance, and insulation aligns perfectly with our commitment to sustainability.”

The project was well received by Tattva.

Richard continues: “Working with Tattva has been an exceptional experience. Their professionalism, scientific expertise, and commitment to innovation have been evident at every stage of our collaboration. Their rigorous approach to developing Stromate and their ability to translate groundbreaking research into real-world applications make them a valued partner in advancing sustainable construction materials.”

Support from UKRI for novel biomaterial

Tattva, has been awarded a £650k (as part of an overall £950k application) Innovate UK Smart Grants from the UK government —to scale its breakthrough CO2 sequestering process and build the foundations of a pioneering cyanobacteria discovery platform.

A pilot plant has already validated that the raw material can scale, with panels of the biomaterial being used in a living building at the St Andrews Botanic Garden in Scotland.

Prantar comments: “This funding provides a consider endorsement of our unique biomaterial. I am very grateful to my PhD supervisors Dr. Brenda Parker, UCL Biochemical Engineering and Prof Marcos Cruz from UCL Bartlett School of Architecture for their support and encouragement, which has helped us get to this stage.”

More information

To read more about Tattva – www.tattva.bio/