The challenge of storing energy generated by wind and solar is widely recognised. The current technology is 90% efficient and offers clean energy, but it has geographic limitations. This is creating a significant market opportunity for a more flexible innovation that can capture renewable energy and release it on demand.

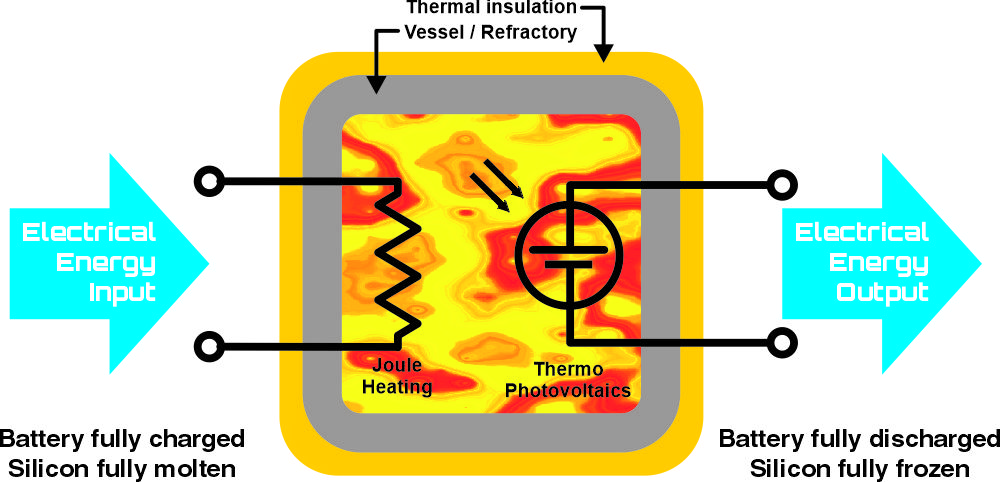

Early-stage ClimateTech company Silbat is offering a revolutionary ‘melting silicon’ battery to address the storage challenge. Silicon is the second most abundant element in the earth’s crust and offers a high fusion heat, the technology is innovative but how does it plan to challenge the incumbent?

Challenging the incumbent – Pumped Storage Hydro backgrounder

A similar storage issue was found with Nuclear Energy, over five decades ago, when it was unable to ramp up and down to meet changing demands for electricity on the grid. The solution in the UK was to state fund the creation of four Pumped Storage Hydro (PSH) schemes in Wales to store the surplus power overnight.

PSH schemes need to be in mountainous areas, as excess power is used to pump water into a high level reservoir. When the energy is needed, the water is released, generating electricity.

According to the International Hydropower Association, PSH provides more than 90 percent of the world’s grid-scale energy storage applications, with 160 GW of installed capacity and 9,000 GWh in energy storage.

It is an established, cost-effective and well understood technology but it does however have a number of disadvantages, it needs to have a suitable geography, new installations require lengthy environmental impact assessments and construction can be time consuming and expensive.

An alternative is battery storage – but current Lithium-ion technology is 50 -80% efficient and relies on rare elements with environmental and human-rights implications, so more innovation is needed.

Case-study: Silbat

Ignacio Luque Heredia is Co-founder of Silbat and its Chief Executive Officer, he is a seasoned entrepreneur with a strong track record in renewable energy. The company is developing a melting silicon battery that utilises the fusion latent heat of silicon to provide long-duration energy storage. Its target is 100 hours at below $20/kWh.

Silbat was the first Spanish company to receive funding from Shell through its Gamechanger Program, which includes expert mentoring on the technical aspects of long-duration energy storage. Ignacio discusses the company’s innovation strategy and the support it is receiving from the industry.

How did you determine the market need?

We actively engage in ongoing discussions with potential end-users, such as renewable energy developers, electric utilities, and oil & gas companies.

Concurrently, we conduct comprehensive analyses of various business cases for our storage system, whether hybridized with renewables or operating as a standalone solution, both behind-the-meter and in front of it, as well as on-grid and off-grid.

Additionally, we collaborate with expert third parties, including market brokers, to perform simulations that evaluate critical market value metrics, such as Levelized Cost of Energy (LCOE), project Internal Rate of Return (IRR), and resiliency criteria, including the system’s survival period during a blackout. This multifaceted approach equips us with the necessary insights to develop a compelling business case for our technology, tailored to meet the specific needs of our potential end-users.

Moreover, at our TRL6 stage, we are progressing beyond the power-to-heat-to-power (P2H2P) operation mode to incorporate heat delivery capabilities (P2H) within the same unit, producing steam at temperatures of up to 300°C.

This advancement unlocks a significant Total Addressable Market (TAM) across a diverse array of industries, including distilling, nitrate melting, dyeing, and compression. We are applying the same rigorous application analysis approach for these new capabilities as we have for the P2H2P case, ensuring that we fully understand the market implications and opportunities.

What is your business model?

Our technology primarily functions as a systems integration solution, leveraging existing industrial components available in the market.

The only area where we are pioneering a new industry is in thermophotovoltaics (TPV) where we are among the first to develop high power density TPV modules. Research on TPV began in 2011 at the Institute of Solar Energy of the Technical University of Madrid (IES-UPM), a leader in photovoltaic solar energy since 1981. It was their expertise in silicon, combined with extensive experience in TPV, that has enabled us to establish Silbat as a spin-off in 2019. Transforming early-stage research into a commercial product. This relationship continues and we have filed several patents with IES-UPM.Fortunately, the industrialization of

TPV can strongly leverage the established photovoltaic industry, particularly in the realm of III-V semiconductors, whether for epitaxy or cell processing. This synergy not only facilitates our integration into the existing value chain but also enhances the overall efficiency and scalability of our technology.

We are also supported by key corporate shareholders, including oil and gas giant Baker Hughes, Spain’s renewable energy leader Soltec Power Holdings, and the European Commission’s Greentech accelerator, KIC InnoEnergy. Currently, Silbat’s product development has reached Technology Readiness Level 5 (TRL5) and we are advancing towards TRL6, with plans to achieve market readiness by 2028.

Bringing the melting silicon battery to market

We plan to build a manufacturing business for our technology, which will progress through three main phases.

- The first phase (2028 and 2029), will focus on validating the technology at the sites of our early clients, aiming to achieve TRL9 along with product certification.

- Second phase (2030 to 2034), will be the scale-up of production to the hundreds of units, primarily targeting the off-grid, resiliency, and backup power markets. The focus will be reducing CAPEX to below $20/kWh.

- Third phase will be the transition to mass-scale manufacturing of Long-Duration Energy Storage (LDES) and Medium-Duration Energy Storage (MDES) products.

Does something need to change to facilitate the adoption of your technology?

Yes, to facilitate the adoption of our technology, several changes are necessary, particularly in the realm of regulations and industry mindset.

Stationary storage, whether behind or in front of the meter, is still in its early stages. While the advantages of storage are clear—enhancing the economics and reliability of the grid and improving its efficient management by end users—this sector remains highly regulated and many of the benefits associated with energy storage require supportive regulation to be fully realised.

However, these regulatory frameworks vary significantly across countries, which can create challenges for widespread adoption.

Fortunately, we are witnessing a positive trend, as regulations around the globe are adapting to better leverage the benefits of energy storage.

This evolution is happening at a relatively quick pace, and we believe that by the time we are market-ready, the barriers to adoption will be significantly reduced.

Useful information

More about Silbat’s melting silicon battery.

More about Pumped Storage Hydro(PSH) from the British Hydropower Association (BHA)