The intermittent nature of renewable energy generated from wind and solar is a currently a challenge to wider electrification of industry and the economy. Introducing Green Hydrogen into the mix offers the potential to store surplus energy and balance the grid, but there are still many technical, logistic and policy changes needed before it is widely adopted.

There are many emerging innovations with potential to overcome these obstacles, but do they have right business model to become a contender?

When is hydrogen ‘green’ – backgrounder

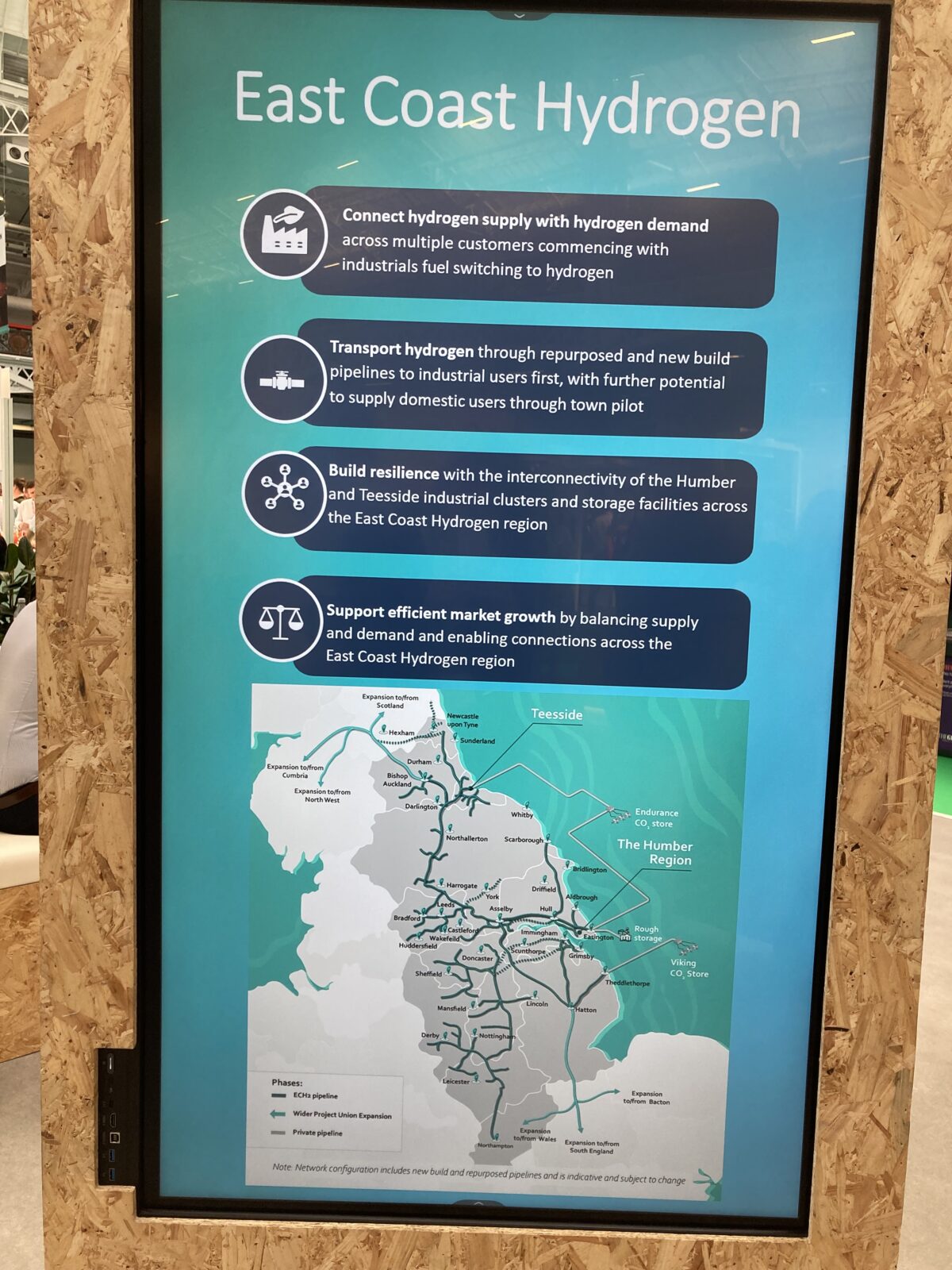

Hydrogen will play a key role in sectors such as heavy industry and long-distance transport that are hard to decarbonise. The sector is progressing rapidly and many geographic regions are considering a low-carbon hydrogen strategy (see right) in preparation for the technology being able to scale and become competitive in price.

Hydrogen can be made in a variety of ways, for example ‘blue hydrogen’ is produced using natural gas but produces carbon as a by-product – so not all hydrogen is ‘green’.

Green hydrogen is produced by using electricity from renewable sources to power an electrolyser that splits the hydrogen from water molecules. This process produces pure hydrogen, with no harmful by-products. An added benefit is that it offers the potential to convert any excess electricity that is hard to store (like surplus wind power) into a hydrogen gas that can be stored for future energy needs.

Another advantage of hydrogen, is that there is potential for it to use the existing gas infrastructure that is used for heating and cooking and there are already cars that run on hydrogen fuel cells.

Electrolysers are therefore a key technology. Alkaline and PEM (proton exchange membrane) electrolysers are already commercially available, while Solid Oxide Electrolysis (SOEC) is quickly approaching commercialisation and Anion exchange membrane (AEM) electrolysers are at earlier stages of development.

Case-study: Electrogenos

Augusto Bartolome, co-founder and CEO of Electrogenos explains discusses the innovation management decisions the company has made to introduce its revolutionary electrolyser technology to the energy sector at a time of rapid change.

Does your technology address a clearly articulated industry challenge?

Yes, Electrogenos’ technology directly addresses critical challenges that have been widely recognized by the green hydrogen industry:

- High cost of green hydrogen production: Green hydrogen today remains significantly more expensive than fossil-based alternatives, with production costs ranging from $6 to $8 per kilogram. This cost barrier is one of the main obstacles to widespread adoption. Electrogenos responds to this challenge by introducing a highly efficient alkaline electrolyser system that can produce hydrogen at a Levelised Cost of Hydrogen (LCOH) as low as $3/kg, assuming electricity prices of $52/MWh. This represents up to a 30% reduction in production cost compared to current benchmarks, making green hydrogen far more competitive.

- Low efficiency of electrolyser systems: Most alkaline and PEM electrolysers operate below 75% efficiency, which limits their economic and environmental performance. Electrogenos overcomes this limitation with a proprietary stack design that achieves 94% efficiency at 0.5 A/cm² (42.1 kWh/kg) and still maintains 80% efficiency at 2.0 A/cm² (49.0 kWh/kg). These figures have been independently tested by an independent institution.

- High equipment and manufacturing costs: Electrolyser stacks from Western manufacturers typically cost between $300–450/kW, while even the most cost-effective Chinese alternatives remain at $120/kW. In contrast, Electrogenos manufactures its stacks at just $85/kW by leveraging a proprietary wet chemical process that is automated, modular, and six times faster than conventional approaches. The process also dramatically lowers capital expenditure requirements and labor dependency, enabling scalable local production with up to eight times lower CAPEX than competitors.

- Reliance on scarce and expensive materials: Many electrolyser technologies rely on platinum group metals (PGMs), which are costly, geopolitically sensitive, and environmentally intensive to extract. Electrogenos eliminates this dependence by using a proprietary transition metal alloy catalyst that is 50 times cheaper than platinum-based options.

- Mismatch between renewable energy Intermittency and electrolyser design: Traditional electrolysers struggle to adapt to the intermittency and variability of renewable energy sources such as wind and solar. Electrogenos’ system, however, is specifically engineered to thrive in these conditions. It features low onset potential, fast voltage response, and excellent resistance to reverse polarisation—all critical capabilities for efficient operation in fluctuating power environments. The stack can seamlessly shift between high-efficiency mode and high-throughput mode, optimising for electricity price fluctuations and enabling flexible deployment in both grid-connected and off-grid scenarios.

2. Is your technology a direct substitute for an existing technology?

Yes, Electrogenos’ technology is a direct substitute for existing electrolyser technologies used in green hydrogen production. There are a number of incumbent approaches currently dominating the market, and Electrogenos offers a step-change improvement in both cost and performance compared to them.

The incumbent alkaline water electrolysis (AWE) systems, such as those that rely heavily on Raney nickel catalysts, exhibit lower efficiency and activity. Electrogenos’ catalyst is not only over 10 times cheaper than Raney nickel (at approximately $27/m² vs. $300/m²), but also delivers twice the activity of platinum (an alternative to nickel), reducing the number of electrodes required and halving system costs.

In head-to-head comparisons, Electrogenos achieves up to 5 times more hydrogen output at the same efficiency as Raney nickel systems operating at 1.8 V, or alternatively, saves 0.25 V while producing the same hydrogen output at 0.5 A/cm².

Importantly, Electrogenos completely eliminates the use of platinum group metals, offering a 50x catalyst cost advantage, enhanced scalability, and lower supply chain risk.

In sum, Electrogenos’ stack and catalyst system is a true plug-in substitute that can be adopted by existing OEMs, EPCs, and industrial hydrogen producers with minimal adaptation, but major economic and operational gains.

3. Does your technology fit within the existing value chain – if not, what needs to change?

Yes, Electrogenos’ technology fits seamlessly within the existing hydrogen value chain and is designed to enhance, not disrupt, the way electrolyser systems are integrated, manufactured, and deployed.

The technology is fully compatible with current industry standards and interfaces, allowing stakeholders such as OEMs, EPC firms, and industrial gas providers to adopt Electrogenos’ stacks and catalysts without needing to overhaul their infrastructure or workflows.

Electrogenos aims to manufacture electrolyser stacks (data structures), which are a core component of existing alkaline electrolysis systems. These stacks can be directly integrated into broader systems that include the balance of plant, power electronics, water management, and safety systems already used by hydrogen producers. As such, OEMs can incorporate Electrogenos’ stacks to replace or upgrade their current stack modules, boosting performance and cutting costs without modifying the rest of their system architecture.

For EPC companies and industrial gas providers, Electrogenos will enable modular sourcing of high-performance components. These actors can continue assembling their own electrolyser systems but benefit from using Electrogenos’ advanced stack technology to reduce CAPEX and OPEX while improving efficiency.

Some of the Electrogenos team in 2023

4. What is your business model?

Electrogenos operates a direct sales business model, focused on supplying high-performance alkaline electrolyser stacks to key players across the hydrogen value chain.

Our primary revenue will come from the sale of stacks, designed to integrate seamlessly into broader electrolyser systems or hydrogen production plants. This model allows us to scale commercially while maintaining control over quality, performance, and margins.

We serve four main customer types.

- OEMs (Original Equipment Manufacturers) integrate our stacks into their electrolyser systems to boost efficiency and lower manufacturing costs.

- EPC (Engineering, Procurement, and Construction) firms source our stacks as best-in-class components for assembling full hydrogen production facilities.

- Industrial gas providers purchase standalone stacks to build and operate decentralised hydrogen plants, leveraging their in-house expertise in balance-of-plant design.

- End users in sectors like steel, ammonia, and refining use our stacks to produce green hydrogen on-site, enabling them to reduce reliance on grey hydrogen and improve overall cost competitiveness.

This model positions Electrogenos as a component supplier of choice for scalable, cost-effective hydrogen production, enabling broad market reach without the capital intensity of full system manufacturing.

5. What has been the response from potential end-users for your technology?

Electrogenos has already engaged with multiple potential end-users of its technology and is actively collaborating with them through pilot programs and early-stage validation efforts. These engagements provide the company with strong insight into user needs and system-level requirements, which serve as a foundation for building tailored business cases.

One of the key end-user relationships is with Repsol, where Electrogenos is currently developing a 20kW proof-of-concept in collaboration with Repsol’s technical teams. This partnership is focused on validating performance under real industrial conditions and directly informs the scalability and integration of Electrogenos’ stack into megawatt-scale projects. The individuals involved are likely technical leads or engineering managers responsible for new technology evaluation and hydrogen deployment within Repsol’s clean energy division.

Electrogenos has also received endorsement from the All4Zero think tank, which includes major industry stakeholders such as Iberia, Holcim, and ArcelorMittal. While not formal customers yet, their recognition of Electrogenos’ cost-saving and performance potential demonstrates industry validation.

Regarding the business case, Electrogenos has developed detailed cost and performance models, including comparisons of Levelised Cost of Hydrogen (LCOH), stack pricing, efficiency metrics, and ROI calculations under various electricity price scenarios.

6. Does something need to change to facilitate the adoption of your technology?

While Electrogenos’ technology is designed to fit seamlessly within the existing hydrogen value chain, several enabling conditions would accelerate and facilitate its widespread adoption and create a more favorable environment for scale-up.

- Regulatory support plays a crucial role. Although Electrogenos’ electrolyser stacks are already cost-competitive, their adoption is greatly facilitated by policies that incentivise the use of green hydrogen, such as the EU’s Renewable Energy Directive (RED III), which mandates 42% renewable hydrogen use in industry by 2030. The company is already aligned with these frameworks, but continued and expanded regulation, especially regarding content requirements (like the EU Hydrogen Bank’s preference for non-Chinese components), would further boost demand for localised solutions like Electrogenos’.

- A change in cost-base – this is happening — and Electrogenos directly supports this shift. As electricity prices fluctuate, especially with growing renewable penetration, technologies that can dynamically adapt to price signals and operate efficiently under variable loads are increasingly valuable. Electrogenos’ stack can switch between high-efficiency and high-throughput modes, making it ideal for leveraging these fluctuations. This ability supports a broader economic shift toward using surplus renewable energy for hydrogen production — but its full value is unlocked as renewables become the dominant grid source, reinforcing the trend.

- Industry shift from fully integrated, off-the-shelf electrolyser units. A switch to a modular sourcing model allows for more flexible system design but requires internal capacity to integrate components — a shift that may require some adaptation in procurement and engineering practices.

- Continued development of adjacent enabling technologies. Technologies such as smart grid integration, hydrogen storage, and infrastructure for decentralized hydrogen production (e.g. in Hydrogen Valleys) will reinforce Electrogenos’ competitive edge. The ecosystem for transport, storage, and regulatory certification must also evolve in parallel to support rapid scaling.

7. Do you see a role for the CleanTech ecosystem in lobbying for change or identifying trends etc. that might support the introduction of Green Hydrogen?

Yes, and its role is urgent. The biggest barrier to green hydrogen scale-up today is not supply—it’s demand, which is being held back by high costs.

Unless the CleanTech ecosystem focuses its lobbying efforts on the real challenge—cost competitiveness—we risk wasting momentum on scaling technologies that cannot deliver economic hydrogen, effectively killing the ecosystem before it begins.

We need coordinated industry analysis and honest exposure of where current solutions fall short. Lobbying needs to shift from broad support for “any” green hydrogen project to targeted mechanisms that enable deployment of next-generation systems that are riskier but essential for unlocking <$2/kg green hydrogen.

More information about Electogenos

More information about the Climate Tech Supercluster