The circular economy (CE) offers a compelling answer to the depletion of finite resources—not as a compliance exercise, but as a design challenge with strategic upside.

The Goldman Sachs Group estimates that CE strategies could unlock up to $4.5 trillion in additional global output by 2030, rising to $25 trillion by 2050. For companies navigating volatile markets, circularity presents a concrete path to reduce material dependency, unlock new revenue models, and strengthen customer relationships—while contributing meaningfully to global sustainability goals.

However, Claus Lang-Koetz Professor of Sustainable Technology and Innovation Management at Pforzheim University, argues that the conventional ‘product perspective’ is not sufficient for adoption of CE and a different type of logic needs to be applied.

In this article he explains how by starting small—examining one product, convening one team, running one workshop—organisations can begin to unlock the creative potential of circular thinking.

How companies can turn sustainability into an opportunity for innovation

In recent years, sustainability has moved from the periphery of corporate strategy to the centre of financial decision-making. A major factor in this shift has been the investment community’s growing awareness of climate-related risks—prompting initiatives such as the Carbon Disclosure Project (CDP), which links sustainability performance to financial transparency.

By 2023, over 23,000 companies—representing around two-thirds of global market capitalisation—were voluntarily reporting their greenhouse gas emissions and decarbonisation strategies via the CDP platform.

This movement towards transparency, supported by policy developments in the European Union and elsewhere, has elevated climate action in boardrooms and positioned sustainability as a credible driver of investor confidence.

Meanwhile, businesses are facing mounting supply chain challenges—from geopolitical dependence on critical raw materials, to regulatory restrictions on hazardous substances, to instability in global transport and energy markets.

Against this backdrop, sustainability must go beyond compliance. It can—and should—serve as a strategic lever for innovation and long-term resilience.

Circular business models: where the real value lies

The Circular Economy offers a compelling framework for this transformation. Rather than focusing solely on efficiency or emissions reduction, the CE calls for a fundamental redesign of how value is created, delivered, and retained. The core principle is straightforward: keep materials and products in circulation for as long as possible by closing, slowing or narrowing resource loops.

However, realising this potential requires more than technical fixes or recycling targets. Traditional models, which hinge on one-time sales and ownership transfer, often fail to reward durability, reuse, or resource efficiency. What is needed is a reimagining of the underlying business model—the mechanisms by which a company creates, delivers, and captures value.

Circular business models (CBMs) are designed with these principles in mind and can take many forms, including

- product-as-a-service models

- lifetime warranties

- reverse logistics systems

- refurbishment schemes

- digital platforms for repair or resale.

These models enable companies to retain control over their products, generate recurring revenues, and deepen engagement with customers.

A growing body of academic and practical research now offers structured CBM “patterns” that firms can tailor to their industry and strategic goals—turning abstract principles into actionable solutions.

The circular economy in action – case-studies

Several leading examples illustrate how circular thinking can deliver strategic advantage.

Pay-per-wash – Gorenje’s novel leasing model

Slovenian appliance manufacturer Gorenje has explored a pay-per-wash business model in which washing machines are leased rather than sold. The machines remain in company ownership across multiple five-year cycles, during which they are serviced, upgraded, and refurbished. This approach not only reduces waste but also generates additional lifecycle revenue and lowers costs for customers—offering a compelling win-win scenario.

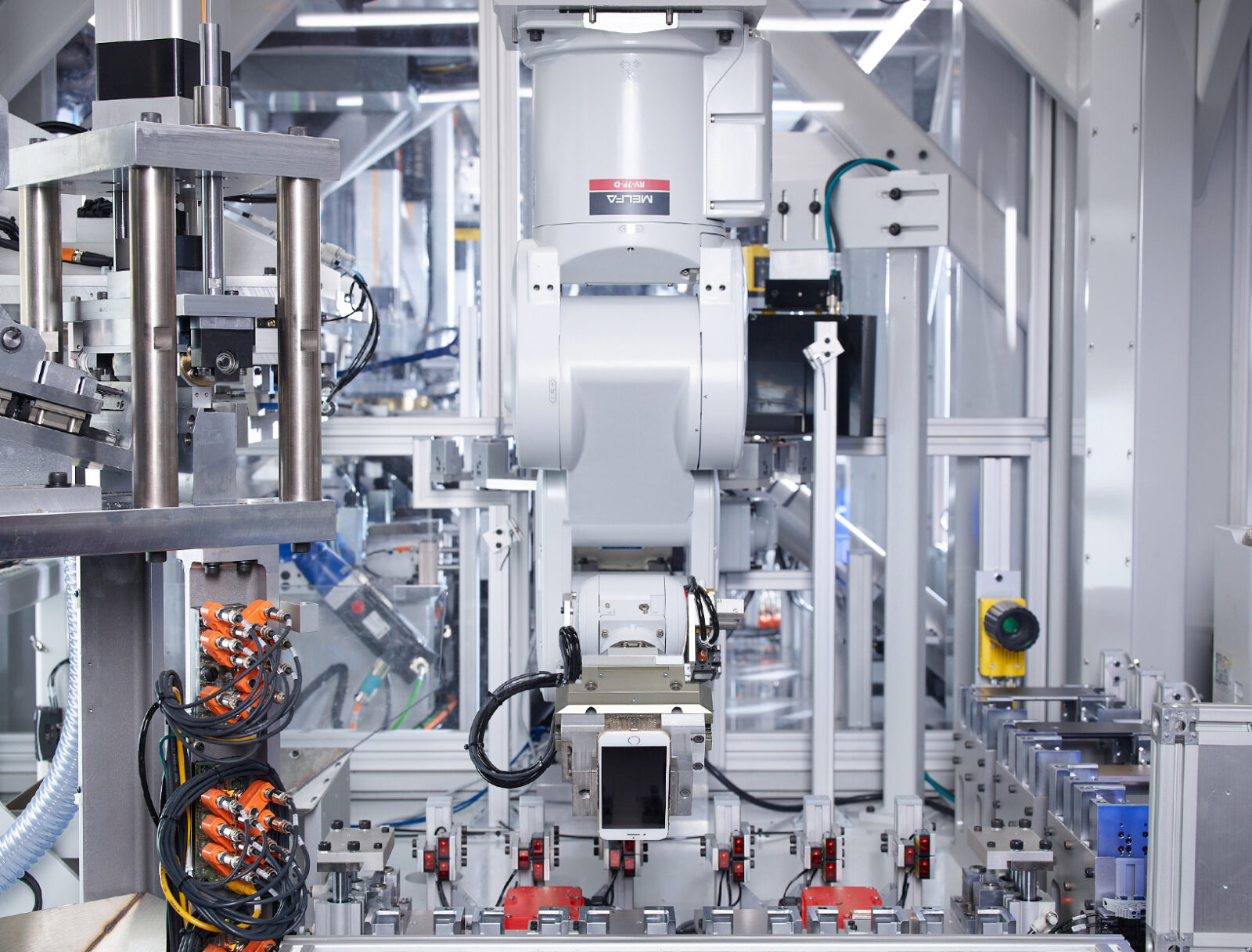

Advanced disassembly robot—DAISY can take apart over one million iPhones each year.

Apple has received nearly 1 million devices through Apple programmes and each Daisy can disassemble 1.2 million devices per year. In 2018, the company refurbished more than 7.8 million Apple devices and helped divert more than 48,000 metric tons of electronic waste from landfills.

These robots are not merely symbolic; they recover valuable and geopolitically sensitive materials such as rare earth elements, cobalt, and tungsten. Apple’s investment in reverse logistics and material recovery is a calculated move to secure supply chain resilience and reduce dependence on volatile markets.

Responsible and premium – everdrop has replaced 19 million plastic bottles

In the consumer goods sector, the German start-up everdrop has disrupted the cleaning product market by eliminating unnecessary water from its supply chain. Rather than selling bulky plastic bottles of diluted soap, the company delivers compact cleaning tablets in compostable packaging. Customers reuse attractive glass containers at home, reducing emissions and packaging waste while enhancing the brand experience. The result is a product that feels both responsible and premium.

From inspiration to innovation: A practical method for generating business models for the circular economy

These examples are inspiring—but how can other organisations generate similar ideas tailored to their own offerings?

This question prompted our team to develop a structured one-day workshop format for circular innovation.

Tested with industrial partners, the format is designed to guide cross-functional teams through a fast-paced, idea-to-action process grounded in their actual products and challenges.

The creativity workshop follows a three-phase structure:

- Logical Phase: Participants begin by examining their current value proposition through a circular lens. Rather than brainstorming in the abstract, they explore where value is lost across the product life cycle—through short usage spans, inefficient design, or missed recovery opportunities.

- Intuitive Phase: Creativity techniques come into play, such as the “Headstand Method”, which challenges teams to consider how they might actively prevent circularity. This reversal often exposes entrenched assumptions and reveals unexplored pathways. A deck of “Make it Circular” cards—derived from circular business model research—provides further inspiration. These resources are freely available from Circular Economy Initiative Germany.

- Critical Phase: Finally, ideas are prioritised and refined using tools such as the Sustainable Business Model Canvas and an impact-versus-effort matrix. By the end of the session, most teams have developed at least one viable concept ready for prototyping.

Why this approach works

Feedback from participating companies has been consistently positive. The method accelerates learning, demystifies circularity, and translates high-level goals into practical next steps. One key success factor is the balance between inspiration and rigour. Teams are not simply encouraged to “think outside the box”; they are equipped with proven tools and frameworks that ground creativity in business logic.

Equally important, the workshop builds internal momentum. It creates a shared language across functions and empowers employees to see sustainability not as a constraint or a bolt-on, but as a core dimension of strategic innovation aimed at the circular economy.

The case for a circular leap

With economic volatility, supply chain disruptions, and tightening regulations now part of the business landscape, the pressure to adapt is growing. But pressure can also create clarity. Sustainability is no longer a side issue—it is increasingly central to competitiveness, resilience, and long-term value creation.

The question is no longer whether to act, but how imaginatively.

About the author

More about Pforzheim University

Lang-Koetz, C., Wichert, P. and Deterding, L. (2025). Finding Ideas for Sustainability-oriented Innovations: Using Circular Business Models for Innovation. In Applied Circular Economy Engineering (eds J.B. Araujo, H. Hinderer, T. Viere and J. Woidasky). https://doi.org/10.1002/9783527847358.ch12